Links:

3. Local Chemical Distributors

hydroxyethylcellulose where to buy

The viscosity grade of HPMC is crucial as it dictates how a formulation will flow, its stability, and, ultimately, its efficacy. For example, higher viscosity grades typically yield thicker solutions, while lower grades produce more fluid mixtures. Therefore, selecting the appropriate viscosity grade is essential for achieving the desired consistency and performance in formulation.

1. Shin-Etsu Chemical Co., Ltd. Based in Japan, Shin-Etsu is one of the largest producers of specialty chemicals, including MHEC. The company emphasizes advanced technology and strict quality standards.

HPMC Limited Pioneering Innovation in the Modern Era

Significance of Safety Data Sheets (SDS)

Hydroxyethyl Cellulose Suppliers A Vital Component in Various Industries

Redispersible latex powder (RDP) is an essential material in the construction and manufacturing industries, known for its versatility and crucial role in improving the properties of various formulations. Comprising small polymer particles, RDP can be mixed with water to create a stable emulsion, offering numerous advantages for a range of applications, notably in cement-based products, adhesives, and coatings.

Exploring the HPMC Website A Gateway to Healthcare Solutions

The degree of substitution (DS), which indicates the average number of hydroxyl groups replaced by methyl or hydroxypropyl groups, plays a critical role in determining the solubility, viscosity, and gelation properties of HPMC. Products with a higher DS tend to be more soluble in water and exhibit lower viscosity.

What is Redispersible Latex Powder?

Hydroxyethyl Cellulose Viscosity and Concentration Dynamics

Preparing HPMC gel is a straightforward process that requires careful attention to detail to ensure optimal results. By following the steps outlined above, one can create a stable and effective gel suitable for various applications. Whether utilized in pharmaceuticals, cosmetics, or food products, HPMC gel's versatility and efficacy make it a valuable material in formulation science. With the correct preparation techniques, the potential for innovation and application is vast, opening doors to new formulations and products that meet consumer needs.

EIFS uses RDP to enhance the system's flexibility and crack resistance, providing a durable and aesthetically pleasing exterior finish.

A Comprehensive Guide to HPMC Gel Preparation

2. Pharmaceuticals HEC is employed as a binder, film former, and stabilizer in various pharmaceutical formulations, including tablets and topical ointments. Its non-toxic nature and compatibility with different drug components make it a preferred choice for formulators.

Understanding Propyl Methyl Cellulose Properties and Applications

What is HPMC?

The primary function of cement adhesive additives is to enhance the adhesion properties of cement mixtures. In construction, ensuring a strong bond between different materials is vital for structural integrity and longevity. For instance, when cement is used in conjunction with tiles or stones, the adhesive properties can dictate how well these materials hold together over time. High-quality adhesive additives can prevent delamination, cracking, and other forms of structural failure.

What is Hydroxyethyl Cellulose?

Applications in the Construction Industry

1. Raw Material Costs The primary raw materials for producing HPMC are cellulose and various chemicals used in the modification process. Fluctuations in the prices of these raw materials significantly affect the overall cost of HPMC powder. For instance, if the cost of sourced cellulose rises due to supply chain disruptions or increased demand in other industries, manufacturers often pass these costs onto consumers, leading to higher HPMC prices.

The Role of HPMC Suppliers

3. Construction Sector HPMC grades are also integral to construction applications, particularly in tile adhesives, plaster, and mortar. They enhance the workability and adhesion properties of these construction materials, ensuring durability and effectiveness.

In the pharmaceutical industry, HPMC is a key ingredient in many formulations, including tablet binders, coatings, and controlled-release drug delivery systems. Its ability to form a gel and swell in the presence of water makes it an ideal choice for products requiring sustained release of active ingredients. Moreover, HPMC is commonly used in ophthalmic solutions and as a thickening agent in various topical preparations, contributing to improved bioavailability and patient compliance.

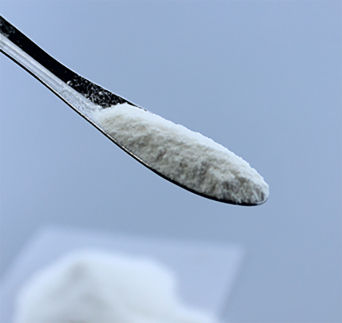

hydroxypropyl methylcellulose powder

Construction Industry

4. Market Competition The number of manufacturers in the HEC market can affect pricing structures. An increase in competition typically leads to lower prices as companies strive to gain market share. However, if only a few players dominate the market, they may maintain higher prices due to reduced competition.

hydroxy ethyl cellulose price

4. Construction HPMC is also employed in construction materials such as adhesives and mortars. Its water retention properties and gelation behavior help improve workability and adhesion in these applications.

Role in the Food Industry

Moreover, HEC's role in the construction industry cannot be understated. It is used as a thickening agent in mortars and adhesives, improving flow and application characteristics. Additionally, HEC is employed in the food industry as a stabilizer, contributing to the consistency of sauces and dressings.

One of the primary roles of HPMC in detergents is its ability to act as a thickening agent. The viscosity-enhancing properties of HPMC allow for the formulation of liquid detergents that maintain an optimal consistency. This thixotropic behavior ensures that the product is easy to dispense yet thick enough to adhere to surfaces during the cleaning process. Consequently, the targeted application of these detergents improves their effectiveness, ensuring that they effectively penetrate and break down dirt and stains.

As the demand for HPMC continues to rise, the number of manufacturers has increased globally. Key players in the market include multinational corporations that specialize in chemical manufacturing, as well as smaller companies focused solely on cellulose derivatives. These manufacturers compete not only on the quality of their products but also on pricing, customer service, and innovation.

Conclusion

Pharmaceutical Uses

hydroxypropyl methyl cellulose hpmc

3. Improved Workability Many modern bonding agents contain additives that improve the workability of the mortar. This enables masons to work more efficiently, as the mortar is easier to mix, spread, and finish.

Hydroxyethylcellulose powder is a versatile and valuable ingredient with a myriad of applications across different industries. Its unique properties not only improve product performance but also contribute to the overall consumer experience. As the demand for natural and effective ingredients continues to rise, the significance of hydroxyethylcellulose in various formulations is likely to grow, paving the way for innovative and sustainable solutions. Whether in pharmaceuticals, cosmetics, construction, or agriculture, HEC remains a cornerstone ingredient that supports advancements in technology and product development.

2. Production Methods The manufacturing process of hydroxyethyl cellulose involves various chemical reactions to modify cellulose. Different production technologies yield HEC with varying properties, which can affect the price. Advanced production techniques that ensure higher purity and performance may come at a premium.

Redispersible polymer powders are essential additives that significantly enhance the performance of various formulations in construction, coatings, and adhesives. Their unique properties provide benefits that cater to the evolving needs of different industries, making them a valuable resource for manufacturers seeking to improve the quality and durability of their products. As technology advances, the versatility and potential applications of RDPs are expected to expand, paving the way for innovative solutions in material science.

Understanding HPMC A Versatile Chemical Compound

Food Industry Utilization

3. Construction In the construction industry, HPMC is used in cement-based products, such as tile adhesives and self-leveling compounds. It improves workability, adhesion, and water retention, contributing to the overall quality of construction materials.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, the most abundant natural polymer on Earth. This compound is widely recognized for its unique properties and versatile applications, making it an essential ingredient in various industries, including pharmaceuticals, cosmetics, food, and construction.

In addition to its performance benefits, RDP is valued for its contribution to the sustainability of construction materials. In an era where environmental consciousness is paramount, RDP enables manufacturers to formulate products that require less cement without compromising performance. This reduction in cement use can lead to lower carbon emissions, supporting the construction industry's move towards greener practices.

redispersible polymer powder rdp

One of the primary benefits of HPMC detergent is its excellent emulsifying properties. Traditional detergents often rely on phosphates and other harsh chemicals that can be detrimental to the environment. HPMC, being a plant-derived component, provides a more sustainable alternative. It can effectively disperse oils and reduce surface tension, thus enhancing the cleaning efficiency without the harmful environmental impact.

The development of advanced manufacturing techniques also enables producers to customize HEC according to specific customer needs, whether it involves tailoring the viscosity or enhancing certain characteristics to fit particular applications.

In the food industry, hydroxyethyl cellulose functions similarly as a thickening and stabilizing agent. It helps maintain the desired consistency of sauces, soups, and dressings, while also acting as a suspending agent for solid particles in liquid formulations. As a food additive, HEC is considered safe for consumption and is often labeled with the code E465, indicating its role as an emulsifier and thickening agent.

Despite its numerous advantages, the use of hydroxypropyl methylcellulose is not without challenges. Concerns regarding the sourcing of cellulose and environmental sustainability have prompted industry stakeholders to explore eco-friendly alternatives and ensure responsible sourcing practices. However, ongoing research and development aim to enhance the production processes and reduce the environmental footprint of HPMC.

Applications of HPMC in Different Industries

Moreover, the construction sector makes extensive use of HEC in cement and plaster formulations as it enhances workability and extends the open time of these materials. The increasing demand in these sectors, combined with the global trend towards eco-friendly and sustainable products, is contributing to higher consumption rates of HEC.

1. Exterior wall insulation system:

Once purified cellulose has been obtained, it undergoes an etherification process to introduce hydroxyethyl groups. This is primarily achieved through the reaction of cellulose with ethylene oxide in the presence of a catalyst, often a base such as sodium hydroxide. The reaction typically occurs in a controlled environment to ensure that the etherification is uniform and efficient.